- Fully sealed recirculating cross-roller bearings for dirt immunity

- Swiss-made DC motors and new Deva motion control system provide shop floor reliability

- Super-smooth belt-drives and linear bearings enable long styli to be used without false triggering through vibration

- Automatic tool offset correction and automation options allow integration into fully automated manufacturing cells

- Aberlink's revolutionary easy-to-use measurement software

- Shortest learning curve of any equivalent system - 1 day without prior CMM experience

- Smallest overall footprint of any comparable size shop floor CMM

- Industrial joystick as standard

- Aberlink 3D measurement software for touch probe feature inspection

- Windows based controller

- Renishaw TP20 probe system

- Aberlink probe stylus kit

- Aberlink Ø19mm sphere CMM requalification kit

- User training course - up to 4 trainees

- 12 months full parts and labour warranty

- Free telephone helpdesk support

- Free software upgrades - no maintenance fees or contracts

|

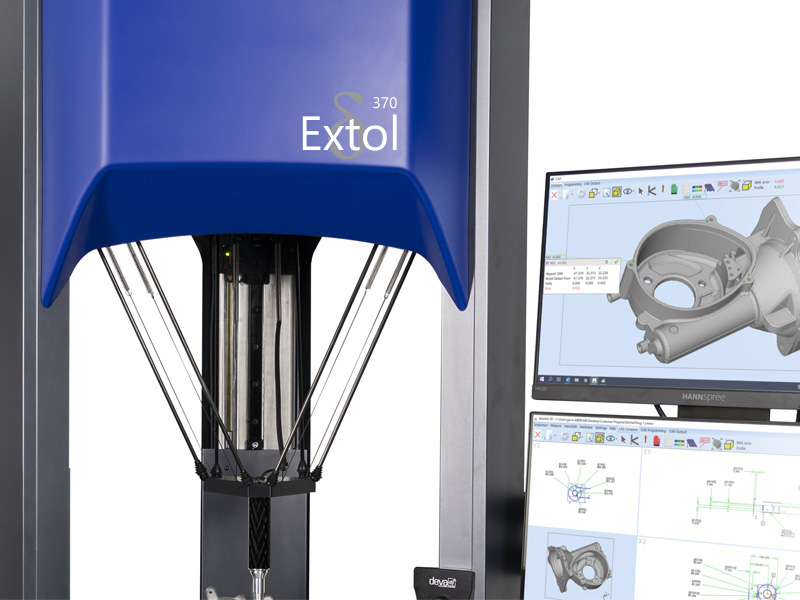

Extol 370 |

Extol 520 |

| Axis Travel (mm) |

XY Dia. 370

Z 270 |

XY Dia. 520

Z 300 |

| Overall Size (mm) |

X 730

Y 715

Z 2000 |

X 990

Y 950

Z 2200 |

| Motion |

CNC |

CNC |

| CMM Structure |

Delta |

Delta |

| Suitable For |

Shop Floor/Inspection Room |

Shop Floor/Inspection Room |

| Drive Type |

Belt (w/linear bearings) |

Belt (w/linear bearings) |

| *Volumetric Accuracy |

TP20

(2.6 + L/250)µm

TP200

(2.5 + L/250)µm

SP25M

(2.3 + L/250)µm |

TP20

(2.6 + L/250)µm

TP200

(2.5 + L/250)µm

SP25M

(2.3 + L/250)µm |

| Scale Resolution |

0.1µm |

0.1µm |

| **Optimum Temp Range |

18 - 22°C |

18 - 22°C |

| Operational Temp Range |

5 - 45°C |

5 - 45°C |

| Table Construction |

Solid Granite |

Solid Granite |

| Table Load Capacity |

200kg |

200kg |

| Max. Velocity Vector |

500mm/sec |

500mm/sec |

| Max. Acceleration Vector |

750mm/sec² |

750mm/sec² |

| Air Required? |

No |

No |

| Air Consumption |

n/a |

n/a |

| Required Air Pressure |

n/a |

n/a |

| Aberlink Camera support |

No |

No |

*The machine should not be positioned where it will be subjected to rapid changes in temperature. Max rate of ambient temperature change should not be more than 1°C/hour.

Ready to find out more?

Request Information